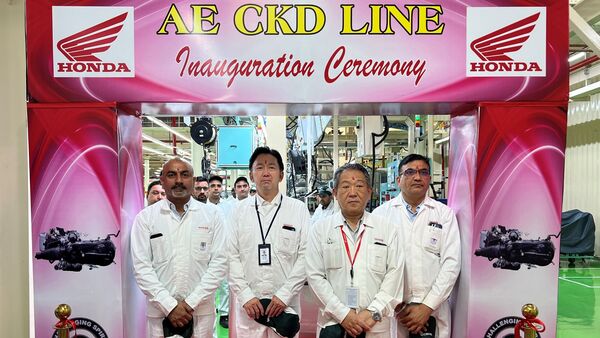

Honda 2Wheelers India inaugurates new CKD engine assembly line at Manesar plant

13 days ago | 5 Views

Honda Motorcycle and Scooter India (HMSI) has inaugurated its new engine assembly line at the Manesar facility in Haryana. The new assembly line has a manufacturing capacity of 600 engines per day and will produce engines ranging from 110 cc to 300 cc for a host of models in the company’s lineup. It will focus on Completely Knocked Down (CKD) exports.

Honda 2Wheeler India’s Global Resource Factory in Manesar has a massive operational setup and is also the headquarters for the brand’s domestic operations. The plant was established in 2001 with the Activa scooter being the first mass-production model to roll out of this facility. Over the years, the facility has evolved into a major export hub and ships vehicles to 58 countries globally including Europe, Central & Latin America, the Middle East, Southeast Asia, Japan, Australia, New Zealand, and SAARC nations.

Speaking about the new engine assembly line, Tsutsumu Otani, Managing Director, President & CEO, HMSI said, "We are happy to introduce a new engine assembly line for CKD exports at our Global Resource Factory in Manesar. It is a testament to our relentless pursuit of driving technological advancements in the industry. With this step, HMSI aims to boost its export capabilities, reaching new heights in market expansion and adherence to global quality standards."

The new Honda CKD engine assembly line will use DC tools for critical torquing. It will also be equipped with a vision camera inspection system and complete traceability of parts and processes. Honda also says there is a dedicated exhaust collection line and an acoustic chamber to inspect engine sound.

Furthermore, the new engine assembly line gets a flywheel assembly automation system for tightening and torquing. There is an automatic piston parts verification system and a small parts interlocking unit for an error-free process. Honda is the second-largest two-wheeler maker in India and exports continue to be a strong part of the company's operations.

Read Also: jaguar land rover cars to be build at tata motor's new tamil nadu plant: reports